Smart mechatronic tools

In the framework of the vertical value chain “Smart Mechatronic Tools,” we primarily want to increase the connection of Slovene toolmakers and prepare them for the challenges of the new industrial revolution – Industry 4.0. The goal is to actively involve all toolkit stakeholders as well as tool users to overcome problems and to find solutions in all areas where weaknesses are manifested.

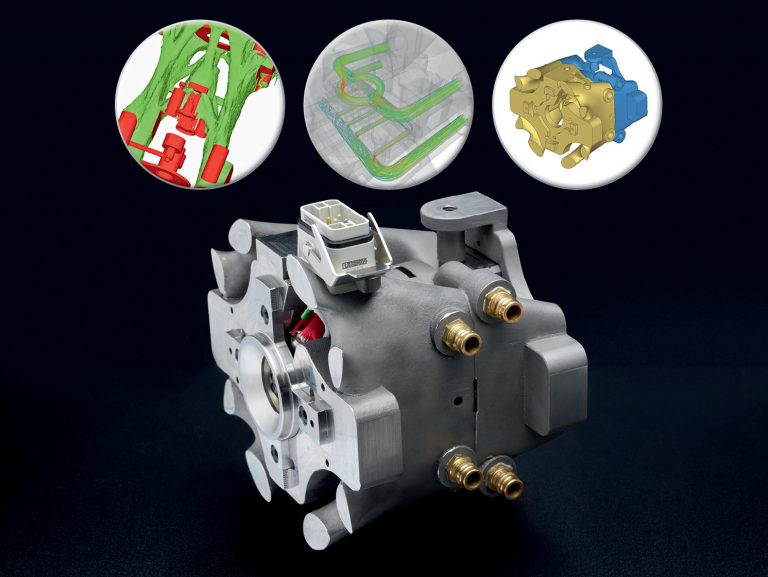

A joint appearance of key actors in the value chain in the field of tooling, which will integrate both stakeholders in vertical value chains and horizontal networks, will lead to a new product, i.e. smart tools that will represent the core of digitized production in companies and will, in the future, largely replace the current classic tools.

The main goal of integration in the value chains is to change the tool from the passive element into an active network element with its own artificial intelligence, which is fully integrated into the Industrial Internet of Things (IIoT). Such a tool will be able to actively monitor the production process in the tool at any time and actively activate the necessary solutions through integrated imaging intelligence, which will eliminate unforeseen events in real time in order to avoid stalled production. In addition to pursuing a key goal for the ultimate product of the smart mechatronics tool, one of the key strategic objectives will be the integration of the following critical development axes that will be faced by companies in the tooling chain in the next ten years:

- Production of micro products

- Production of micro tools

- Micro installation

- Microformation

- Distributed / integrated engineering

- In-Mold Technology (IML / IMD)

- Coatings and surface technologies

- Rapid production and prototype production

- Small-scale production

- New design techniques (Eco-Design)

- Advanced automation, remote monitoring and production cells

- New functional materials

- Innovative environmentally friendly materials (Bio- and Eco-materials)

- Nanotechnologies

- Production of structural composite parts

- Simulation methods and tools for consulting services

- Eco-friendly manufacturing processes

The existing cross-sectional areas have been concentrated mainly in tooling with nanotechnology, robotics and control technologies, but at basic levels.

In the framework of the SRIP ToP, new in-depth cross-sectional areas with HOM such as robotics, control technologies, modern production technology for materials, nanotechnology and photonics, as well as VVVs, such as smart factory, advanced sensors and more widely SRIPs such as

– Information & communication technology (Smart cities and communities),

-Development of materials as final products,

-Networks for the transition to a circular economy and others.

Coordinator

dr. Aleš Hančič

TECOS, Razvojni center orodjarstva Slovenije d.o.o.

Kidričeva ulica 25

SI-3000 Celje, Slovenija

Mail: ales.hancic@tecos.si

+386 3 490 03 20